30% lighter than conventional ready mix

- Weighs up to 30% less than standard ready mix.

- Reduces shrinkage by up to 33%.

- Mold Resistant.

ProForm® Tinted Lite™ Joint Compound is a lightweight ready mix joint compound. Approximately 30% lighter than conventional weight ready mix, Tinted Lite pulls and sands easier, pocks less, and reduces shrinkage by up to 33%. Tinted Lite Joint Compound is designed for use in finishing gypsum board joints, spotting fasteners, and finishing corner bead.

- Superior finishes; provides a finish with less pocking and pin holing.

- Spreads easier for quicker application.

- Finishes metal corner beads with 2 coats.

- Low VOC content - less than 2 g/l.

- Excellent sanding characteristics.

- Ready to use right from the container.

Availability

- Central Region

- Midwest Region

Specifications

Products that suit any project criteria

Product Details

Applications:

Finishing

Packaging:

Carton

Coverage:

123-140 lbs/9 gal per 1,000 sq ft

Carton Volume:

4.5 gal

Related Resources

Product details and technical documentation

Frequently Asked Questions

Do you have mold resistant ready mix?

No material can be considered “mold-proof,” nor is it certain that any material will resist mold or mildew indefinitely. However, when used in conjunction with good design, handling, and construction practices, ProForm ready mix can provide increased mold resistance versus standard ready-mixed compounds. As with any building material, avoiding water exposure during handling, storage and installation and after installation is complete is the best way to avoid the formation of mold or mildew.

How much does a pail or carton of ready mix cover?

A good rule of thumb is to use nine gallons of ready mix for every 1000 sq ft of wallboard.

How should ready mix be stacked?

Ready mix pails or cartons should not be stacked more than two pallets high.

What is the shelf life of ready mix?

Nine months in good storage conditions. To prevent spoilage and freezing, maintain temperature at a minimum 50˚F (10˚C) and protect container from exposure to extreme heat and sunlight.

What happens if my ready mix freezes?

While not ideal, ProForm joint compound can go through up to 3 freeze-thaw cycles. Allow material to thaw at room temperature for at least 24 hours. When thawed, turn the container upside-down for at least 15 minutes. Turn pail right-side up, remove the lid and immediately remix with an electric drill. Ready mix should be lump-free and ready to use within 1 minute. Discard ready mix that does not remix to a lump-free consistency.

Tips & Tools

Detailed information to support your next project

How to choose the right ready mix joint compound

See which joint compounds work well regardless of the level of finish you need to achieve

View

When to use setting compounds vs. ready mix

Expert insight on the best reasons to consider setting compounds

View

ProForm Materials Estimator

Take the guesswork out of materials needed for your project

ViewCompare Products

Ready Mix

ProForm® Tinted Lite™ Joint Compound

Product Type

- Ready Mix

Product Category

Lite Weight

Packaging

Carton

Description

Designed for use in finishing gypsum board joints, spotting fasteners and finishing cornerbead.

Factory Built Housing

ProForm® Lite Blue® Joint Compound

Product Type

- Factory Built Housing

- Ready Mix

Product Category

Lite Weight

Packaging

Carton, Pail

Description

Designed for use in finishing gypsum board joints, spotting fasteners and finishing cornerbead.

Ready Mix

ProForm® Ultra Lite® All Purpose Joint Compound

Product Type

- Ready Mix

Product Category

Lite Weight, Specialty

Packaging

Carton, Pail

Description

Ultra Lite is approximately 40% lighter than other conventional all purpose ready mix products and is ideal for all phases of finishing.

Ready Mix

ProForm® Lite Joint Compound

Product Type

- Ready Mix

Product Category

Lite Weight

Packaging

Carton

Description

Designed for use in finishing gypsum board joints, spotting fasteners and finishing cornerbead.

Ready Mix

ProForm® Lite Blue® with Dust-Tech® Joint Compound

Product Type

- Ready Mix

Product Category

Lite Weight, Low Dust, Specialty

Packaging

Carton, Pail

Description

Vinyl base ready mix joint compound specifically formulated to reduce airborne dust while sanding.

Ready Mix

ProForm® Taping Lite Joint Compound

Product Type

- Ready Mix

Product Category

Lite Weight, Specialty

Packaging

Carton

Description

Lightweight vinyl base ready mix joint compound that may be used directly from the container.

Ready Mix

ProForm® Lite with Dust-Tech®

Product Type

- Ready Mix

Product Category

Lite Weight, Low Dust

Packaging

Pail

Description

Vinyl base ready mix joint compound specifically formulated to reduce airborne dust while sanding.

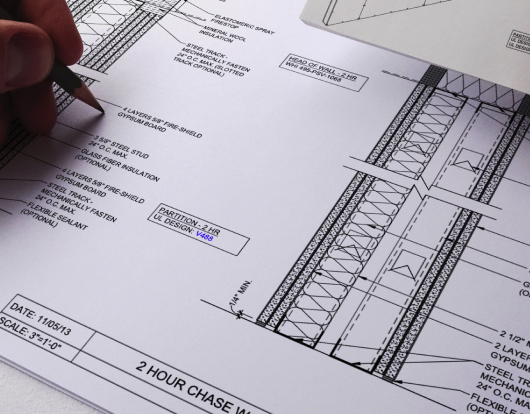

Design & Resources

Review ProForm details and technical information in the Design & Resource Center.

Design & Resource Center

Expert Connection

Contact ProForm representatives who can help troubleshoot your project challenges.

Get StartedNeed Technical Information?

Call 1-800-NATIONAL®

National Gypsum Company is the exclusive service provider for products manufactured by ProForm Finishing Products, LLC.